The company founded by Toby Cattermole and Thomas Diezinger, which will celebrate its 10th anniversary this year, still has great ambitions. Specialising in both primary (TNT Global Manufacturing) and secondary (TNT Promo) custom packaging for the premium industry, the company posted a turnover of USD 52.5 million in 2022. Already established in Hong Kong, Paris and New York, TNT Group will open an office in Shanghai in 2023 while continuing its diversification. Explanations.

With 45 employees worldwide and sales of more than USD 52 million. in 2022, TNT Group is now the leader in zamak packaging components for the beauty industry. The company, which created simultaneously in France and Hong Kong by Toby Cattermole and Thomas Diezinger, has succeeded, in less than 10 years, in becoming a key player for luxury brands.

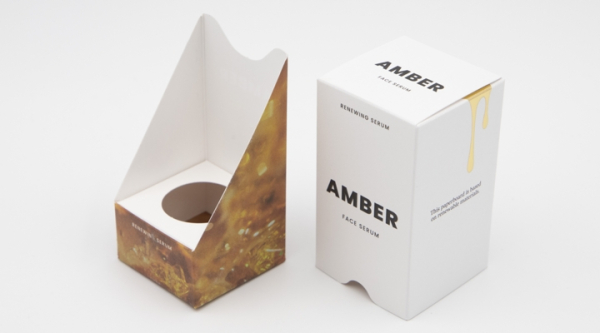

Complex and bespoke design

“We have made a name for ourselves in the perfume category and as zamak component specialists. But we are also experts in a variety of materials and we developing very quickly in new categories, with some great achievements in make-up (for Louboutin, Jimmy Choo or Sisley) as well as in skin care for La Mer, for example,” explains Thomas Diezinger, co-founder.

An example of this complex, all-round know-how is the development of the entire perfume project for the leather goods brand ByFar, with its fully customisable packaging at the POS.

To sustain this diversification, TNT Group leverages its agility and partnerships with the best manufacturers in their sector. “We are a ’fabless’ company, we produce with selected industrial partners, some of whom are exclusive to us. This is a choice. We don’t want to confine ourselves to a particular material or product. Our mission is to produce complex, multi-material designs to meet the requests of our clients. We bring the projects of luxury brands to life by industrialising them,” continues the manager.

TNT Global Manufacturing has chosen not to have a standard range and to focus on specific projects. Depending on requirements, the production of primary packaging and its components (in zamak, stainless steel, aluminium, etc.) can be carried out in Asia and Europe. For promotional packaging and gifts (wooden, paperboard or paper pulp boxes, kits, pouches and bags, wedges), produced by the TNT Promo division, resulting from the acquisition of Promolib in 2020, production mainly takes place in Asia, and a partial reshoring of productions is now underway.

North America and China in focus

As it enters its tenth year in business, the company has high ambitions, with an organic growth target of 10-15% per year for the next five years.

In addition to developing its sales in new categories and consolidating its leading position in Europe, TNT Group, which has had a sales office in New York since 2018, intends to speed up its growth in North America.

Another development area is the emergence of made-in-China niche perfume brands, with the opening of an office in Shanghai later this year. “We want to meet the growing demand of local luxury brands, spurred on by a mixture of national pride and the appeal of self-fulfilment and social belonging. This is a segment in which we have strong ambitions,” warns Thomas Diezinger.

Innovation, luxury and sustainability

Aware of environmental issues and brand commitments focused on sustainability, the company was proactive in creating the very first zamak recovery and recycling channel for perfumes and cosmetics.

“Contrary to popular belief, zamak can be perfectly recycled and there is a well-established recovery channel for this material, thanks to the construction and interior design industries which use large quantities of this material. Yet, to date, the beauty industry had not set up a recovery and sorting system. This is what we initiated in partnership with a retailer and a specialised Belgian company.”

In addition to being an injectable metal, zamak is fully recyclable, with no loss of functional or aesthetic quality. This is how TNT Group was able to produce Bulgari’s Rose Goldea Blossom Delight collar in recycled zamak.

TNT Global Manufacturing also heard its customers’ request to relocate some of its production to Europe. Some parts, in plastic or zamak, can thus be made in Portugal or Italy. “But China remains essential for large volumes and complex assemblies,” stressed Thomas Diezinger.

With its expertise in industrial design, the company also offers its customers various innovations. By recently adapting its patent for a roll-on with a metal head held in place by a magnet on a refill pump bottle, TNT Group has won over a major skincare company, whose product will soon be marketed.

“Demand is high for disruptive designs, which generate buzz on the internet and social networks. Our know-how is perfectly suited to this rapidly growing trend, not only in perfumery but also increasingly in make-up, skincare,” concludes the entrepreneur.

|

For more information about the latest trends and innovations in beauty packaging, check out our latest special issue:

|

Portfolio